Automatic Egg Tray Making Machine

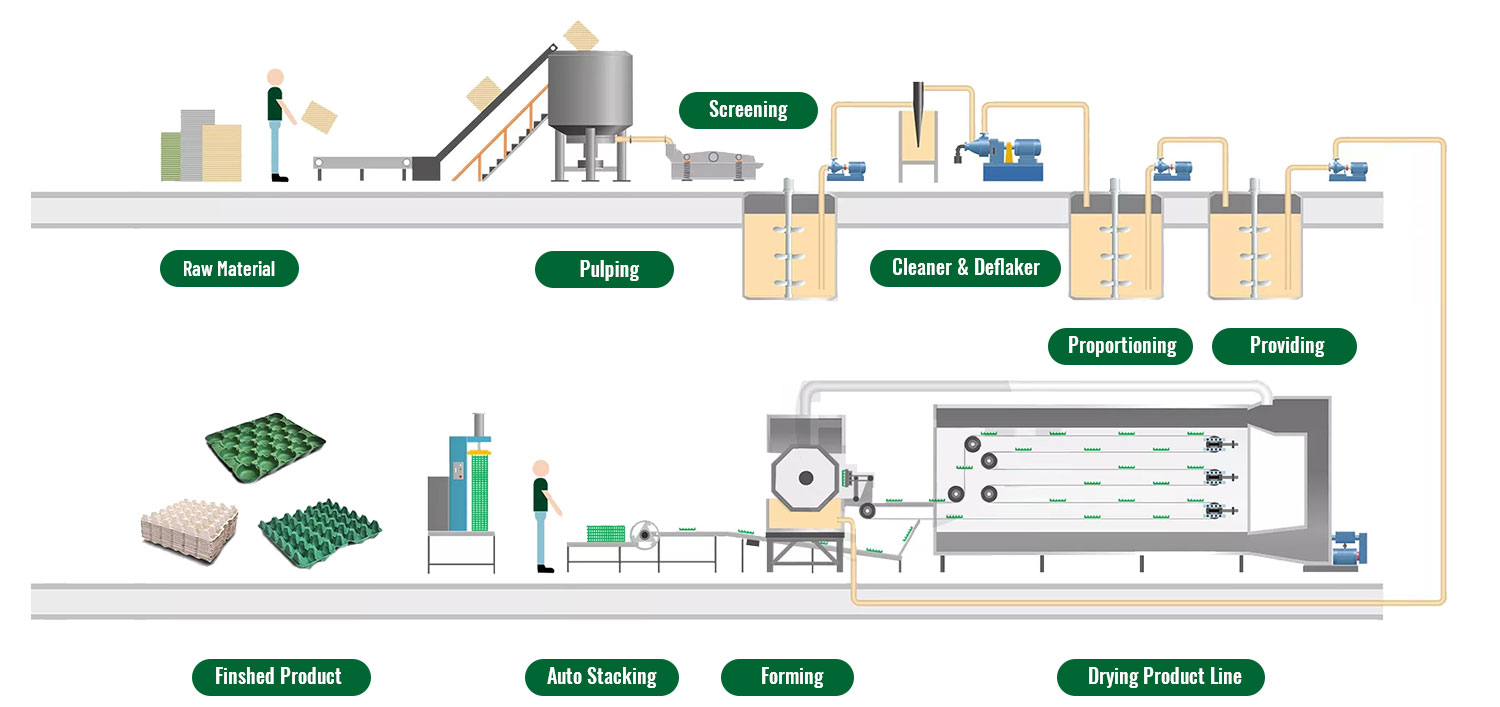

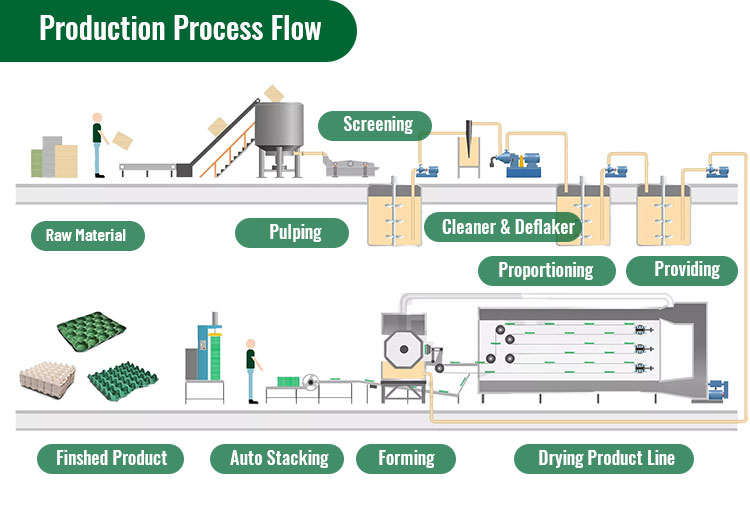

Egg Tray Machine, originally known as Pulp Molding Equipment, utilizes recycled materials such as waste book paper, newspapers, cartons, printing scraps, packaging plant residues, and paper mill tailings to produce biodegradable products including egg trays, cup holders, egg boxes, shoe supports, and protective paper padding for electronics packaging. The production steps are beating – forming – dehydration – drying – packaging. Its drying methods are generally divided into natural drying (drying in the sun), drying box, civil drying, multi-layer metal drying, etc.

Our Molding Technologies

Turnover Type Machine

Rotary Drum Type Machine

Reciprocating Forming Type Machine

| Model | Capacity/H | Power/hour | Paper Consumption/H | Water Consumption/H | Dry System | Weight | Dimensions (Main Machine) |

| YG-4X1 | 1500pcs/h | 38kw | 120kg | 240kg | Dry Naturally | 3000kg | 2800*2200*1900 |

| YG-3X4 | 2500pc/h | 55kw | 200kg | 400kg | Multi-Layer Drying | 4000kg | 2900*1800*1800 |

| YG-4X4 | 3000pcs/h | 60kw | 240kg | 480kg | Multi-Layer Drying | 4800kg | 3250*1800*1800 |

| YG- 4X8 | 4000pcs/h | 95kw | 320kg | 640kg | Multi-Layer Drying | 7000kg | 3250*2300*2500 |

| YG-5X8 | 5000pcs/h | 95kw | 400kg | 800kg | Multi-Layer Drying | 8000kg | 3300*2300*2500 |

| YG-6X8 | 7000pcs/h | 120kw | 480kg | 960kg | Multi-Layer Drying | 10000kg | 3400*2300*2500 |

Application Scenarios

Widely used for producing egg trays, wine packs, fruit pads, seedling pots, and industrial cushioning packaging.

Customer Proof · Global Cases

Why Choose Our Solutions?

Struggling with high operating costs and slow production speeds?

Our automated production lines with intelligent PLC control can help reduce per-unit costs and minimize manual intervention.

Facing complaints about product quality and consistency?

Precision drying technology and standardized processes help ensure better tray strength, uniform dryness, and improved product sanitation.

Experiencing frequent downtime and maintenance challenges?

Equipment built with internationally sourced components is supported by responsive global service and parts availability to help maximize uptime.

Concerned about environmental compliance and waste management?

Features like closed-loop water systems and biodegradable recycled paper materials can support your sustainability goals.

Service & Support

More Than Equipment: A Lifelong Partnership

Pre-Sales

Project Implementation